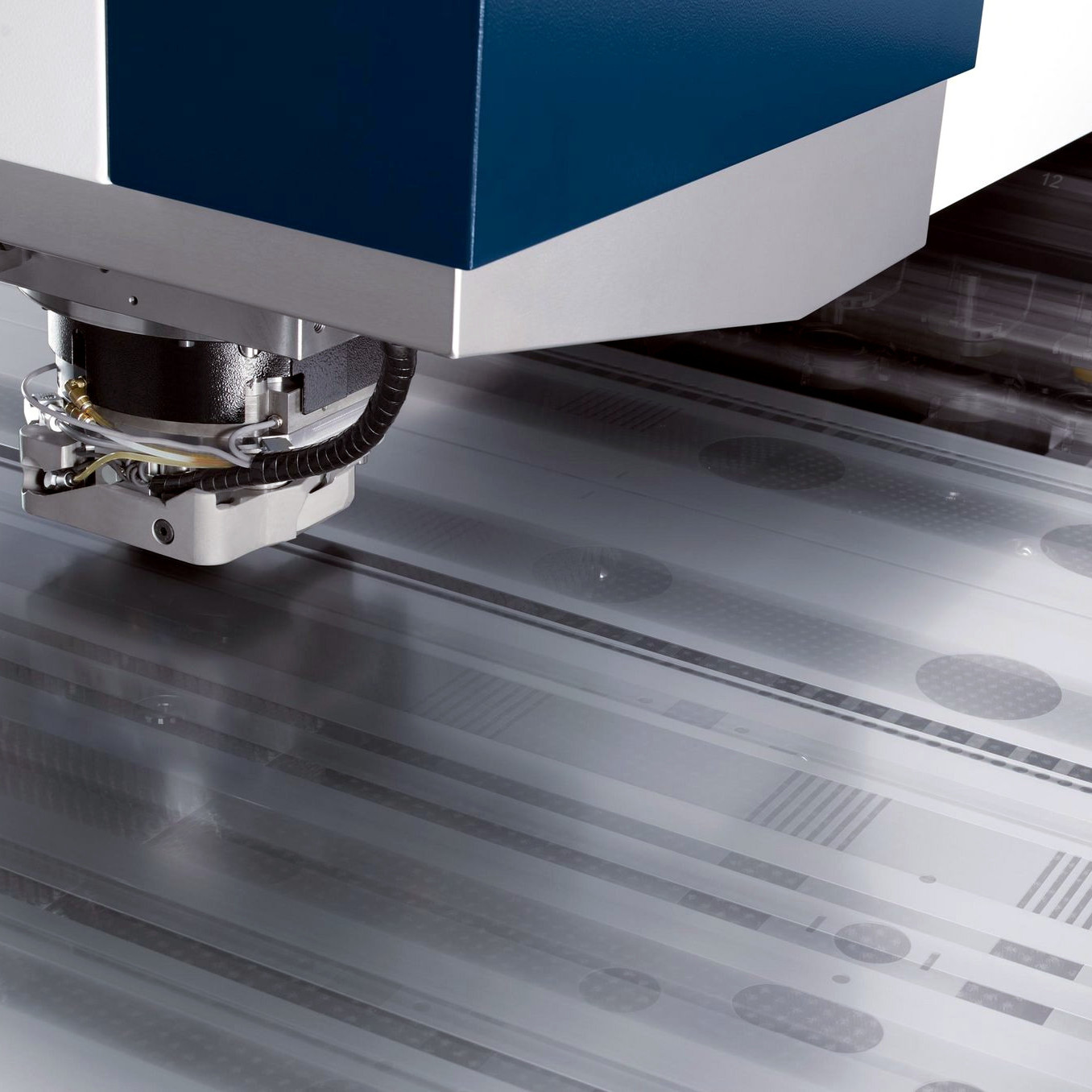

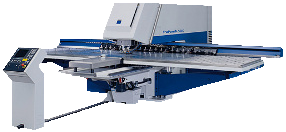

The up-to-date technology of the Trumpf company used by our company enables us to manufacture high quality products with a great precision and flexibility of production. Production can also be tailored to our customers’ needs based on their own drawing plans (provided in dxf, dwg files or in a printed form), possibly also according to a supplied sample.

The up-to-date technology of the Trumpf company used by our company enables us to manufacture high quality products with a great precision and flexibility of production. Production can also be tailored to our customers’ needs based on their own drawing plans (provided in dxf, dwg files or in a printed form), possibly also according to a supplied sample.

Through a cooperation program, the company offers the following:

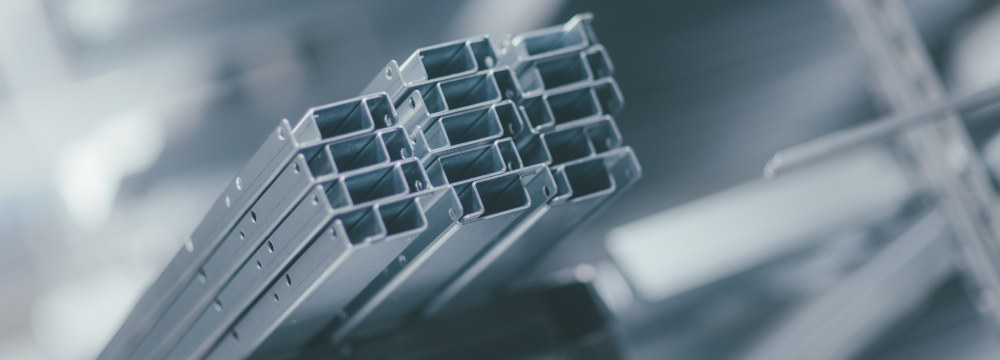

- metal punching and cutting

- metal bending

- stamping

- welding

- lacquering

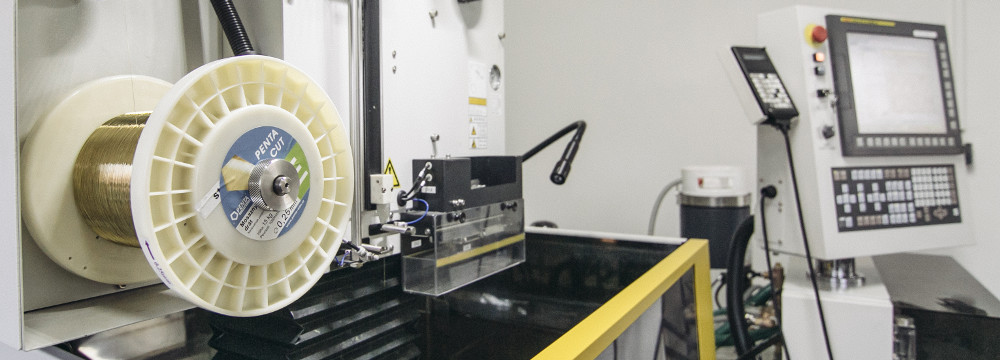

On the CNC punching machines:

Trumatic 200R we produce metal parts and their assemblages. The machine is able to cut out of metal with a thickness of up to 3 mm and a working range of 2000 x 1000 mm and with a precision of +/- 0.03 mm, when clamps are removed, the size can be up to 2550 x 1270 mm.

Trupunch 5000/1600 we produce metal parts and their assemblages. The machine is able to cut out of metal with a thickness of up to 4 mm and a working range of 3000 x 1650 mm and with a precision of +/- 0.03 mm, when clamps are removed, the size can be up to 4050 x 1650 mm.

On CNC edge bending machines:

Trumabend V85SX we produce precise functional parts. The molding force is 85 tons, the edge bending length is 2550 mm.

Trubend 5170S we produce precise functional parts. The molding force is 170 tons, the edge bending length is 4050 mm.