SYSTEM RANGE

Our company has created a quality management system which has been certified according to the ISO 9001 – 2016 standard (ČSN EN ISO 9001 – 2016). This system has been continuously improved. All out-coming results of this system have been thoroughly and regularly filed.

The quality management system covers the following operations:

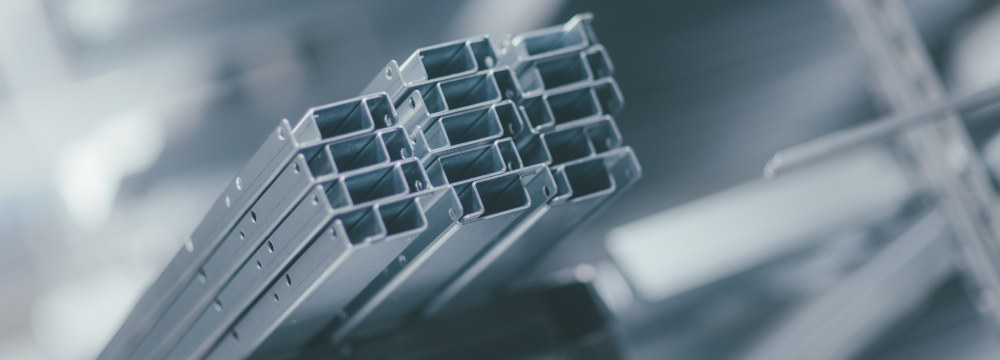

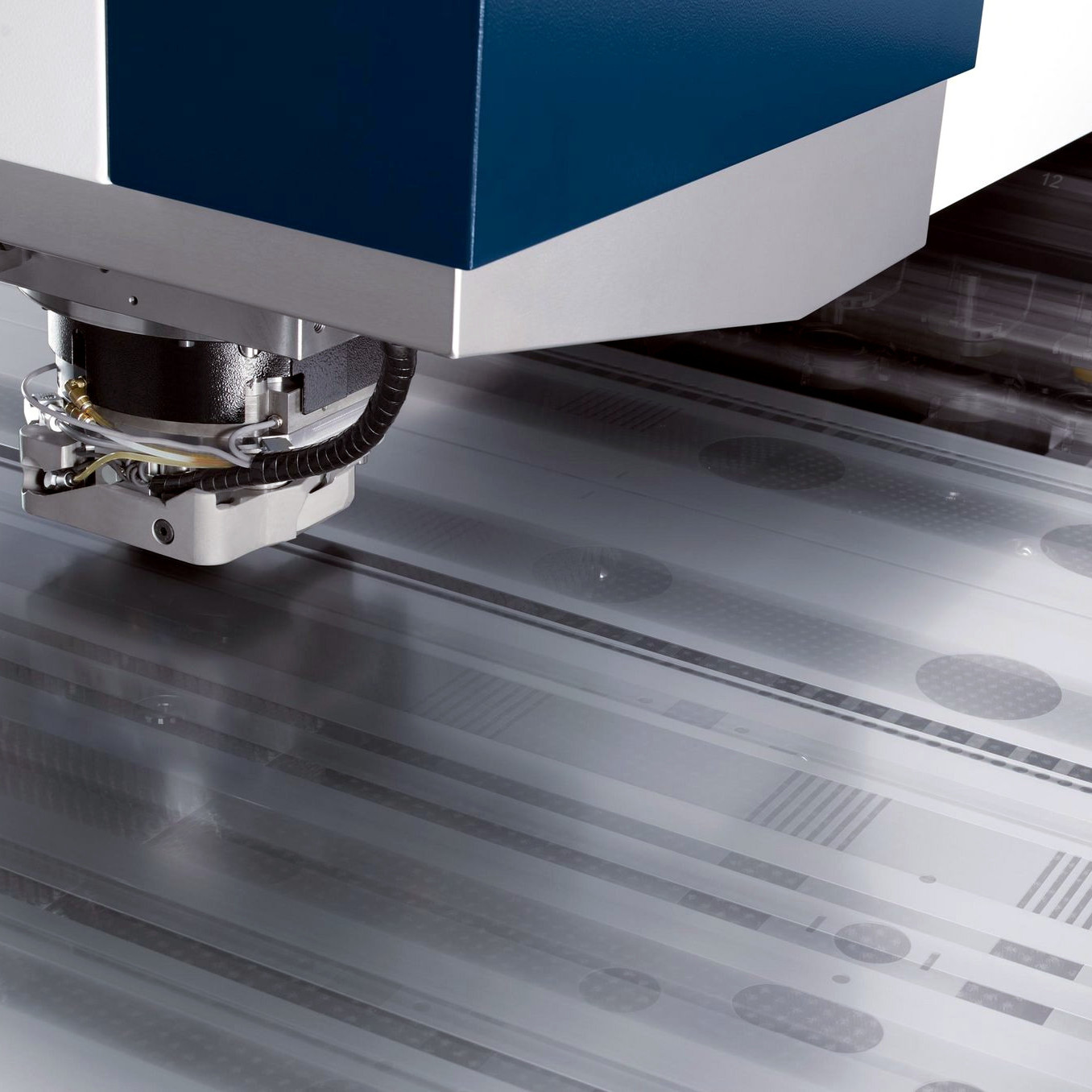

- sheet metal processing (cutting out, bending, stamping, welding) and semi-finished products manufacturing for further processing in other industries

- powder coating for surface treatment of iron, aluminium or zinc products

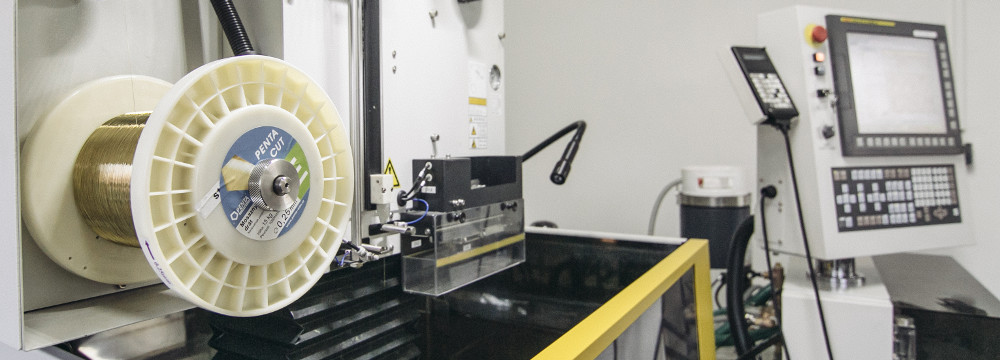

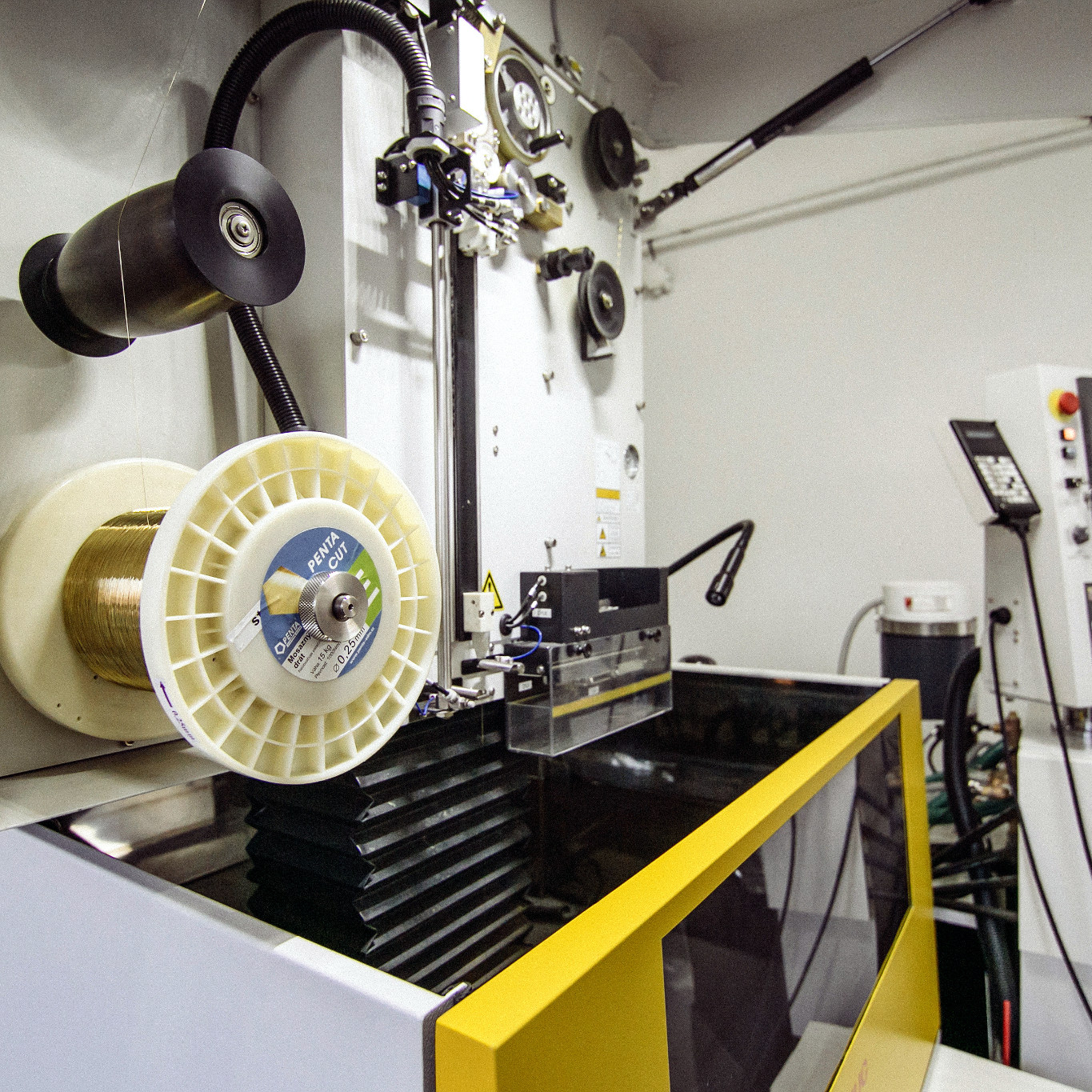

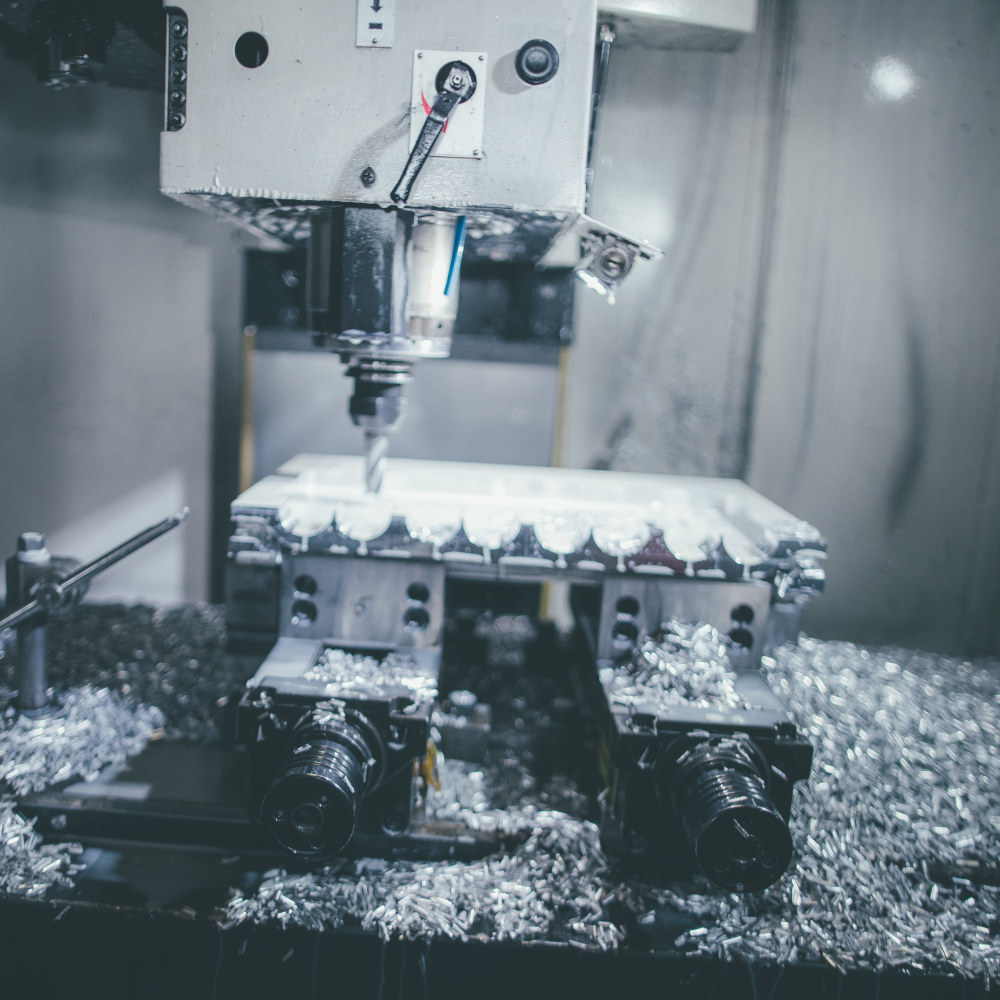

- workshop specialising in construction, manufacturing, servicing and maintenance of shearing, bending as well as drawing tools and other fixtures

All the above mentioned operations are carried out also in compliance with the environmental management system following the ISO 14001 – 2016 standard (ČSN ISO 14001 – 2016) and the health and safety system following the ČSN OHSAS 18001 – 2008 standard. The system does not apply to design or development as our company does not perform these activities.